Copper Earth rods

Copper Earth rods and their fittings are used to provide the interface to ground in all soil conditions in order to achieve satisfactory earthing systems in overhead and underground electricity distribution and transmission networks – providing high fault current capacity on low, medium and high voltage substations, towers and power distribution applications.

Convenient to install where the subsoil condition is free from rock and boulders the earth rod or group of copper rods can be surrounded or backfilled using a low resistance earthing material such as Bentonite.

Depending on the corrosive condition and electrical conductivity of the ground condition the earth rod can be specified to achieve safe, reliable and long term earthing protection – the mechanical strength of the rod must withstand the abrasion and stress endured while installing with an electric or pneumatic driving rod hammer; the head of the earth rod should not “mushroom” or spread when driven.

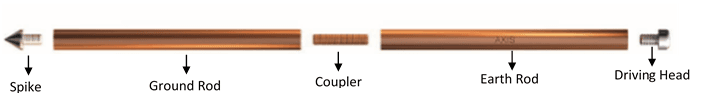

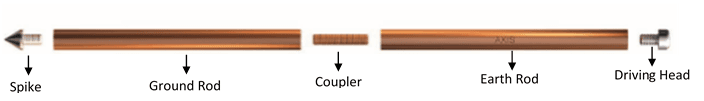

The earth rods, manufactured by AN Wallis, are extendable by design and used with copper couples to inter-connect several rods to achieve the required driving depth – the rod couples provide permanent electrical conductivity and the longer copper earth rods access lower resistivity soils at at lower depths.

Vertically driven earth rods are the most effective electrode for use in typically small area substations or when low soil resistivity ground conditions, into which the rod can where the rod can penetrate, lies beneath a layer of high soil resistivity.

Type of Copper Earth rods material

- Stainless Steel Earth Rods

- Galvanised Steel Earth Rods

- Copperbond Threaded Earth Rods

- Solid Copper Earth Rods

Solid Copper Earth Rods

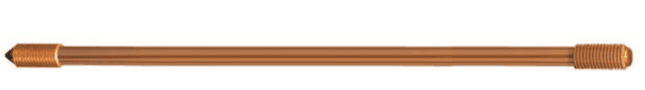

They are one of the best choices for Earth Electrodes. They can be used in areas with high corrosion or in applications where an exceptionally long life is needed. They are also used in installations with high fault currents. These Solid Copper Rods are manufacturing from Solid Copper bars and are then processed to enable jointing. These Solid Copper Rods however are not suitable for deep driving into the ground because of the possibility of bending and are additionally significantly more expensive than the other Rod options.Copper Bonded or Copperbond Earth Rods

They are made using an electroplating process where a layer of Copper is deposited on a steel core. Copper Bonded products offer an advantage over Copper clad products because they are molecularly bonded with the steel core and will thus not slip or tear when they are driven into the ground. Copper Bonded Rods are also significantly more cost effective than Solid Copper Rods while still providing corrosion resistance and low electrical resistance. Additionally, the steel core makes these Copper Bonded Rods more favourable to be driven into the ground.

Thus, Copper Bonded Rods provide high tensile strength using low carbon steel with molecularly bonded 99.9% pure electrolytic copper. This makes Copper Bonded Rods the most economically efficient and popular choice for Earth Rods around the world. Axis has more than 25 years of experience manufacturing and selling Copper Bonded Rods to utilities and other customers in more than 80 countries.

Thus, Copper Bonded Rods provide high tensile strength using low carbon steel with molecularly bonded 99.9% pure electrolytic copper. This makes Copper Bonded Rods the most economically efficient and popular choice for Earth Rods around the world. Axis has more than 25 years of experience manufacturing and selling Copper Bonded Rods to utilities and other customers in more than 80 countries.

Stainless Steel Earth Rods

These Rods are generally used where they may be issues caused by galvanic corrosion because of dissimilar metals buried closed together.

Galvanised Steel Earth Rods

These rods are made up of high strength low carbon steel and hot-dip galvanised. These are the lowest cost rods but also have the lowest corrosion resistance and low electrical conductivity and current carrying capacity.

Benefits of Earth Rods

Earth Rods and their accessories provide high fault current capacity for LV, MV and HV substations, towers and other distribution applications. They can be used for both overhead and underground networks to achieve optimum earthing for distribution and transmission.

Earth Rods are one of the most popular Earth Electrodes used globally because

- Copper Bonded Earth Rods are the most economical method of achieving a low earth resistance.

- They are easy to install in soil conditions that are free from rock and boulders. Copperbond Earth Rods provide high tensile strength using low carbon steel with molecularly bonded 99.9% pure electrolytic copper and thus can be easily driven into the ground with a driving rod hammer without needing to dig a large trench.

- They are designed to be extendable. Highly conductive copper couplers are used to join multiple rods together to achieve the desired length to access lower resistance soil deeper in the ground.

- When space is a constraint, vertically driven rods are a much more space-efficient method of earthing.

- They are corrosion resistant.

- Their compact design makes them easy to store and transport over long distances.

MAXIMUM CURRENT RATINGS OF COPPER EARTH RODS

| Resistivity | Copper Bonded Steel (30%) 16mm Rod Diameter | Solid Copper 16mm Rod Diameter | ||||

| Protection Clearance Time | 1s | 2s | 3s | 1s | 2s | 3s |

| 300Ωm | 40.8kA | 28.8kA | 23.4kA | 69.7kA | 49.2kA | 40.2kA |

| 50Ωm | 31.6kA | 22.3kA | 18.2kA | 54.0kA | 38.1kA | 31.2kA |

| 100Ωm | 22.3kA | 15.7kA | 12.9kA | 38.2kA | 27.0kA | 22.0kA |

| 150Ωm | 18.2kA | 12.8kA | 10.6kA | 31.2kA | 22.0kA | 18.0kA |

| 200Ωm | 15.8kA | 11.1kA | 9.1kA | 27.0kA | 19.0kA | 15.6kA |

Drawing Format: CAD / PDF / DWG / IGS / STEP.

Packaging: Standard package, Carton box or Pallet, As per customized specifications

Shipping: DHL, FEDEX, UPS and By Sea or as per client’s requirements.

We can manufacture and export Brass Products as per specifications (custom drawing and samples) for more information, please

Copper Earth rods